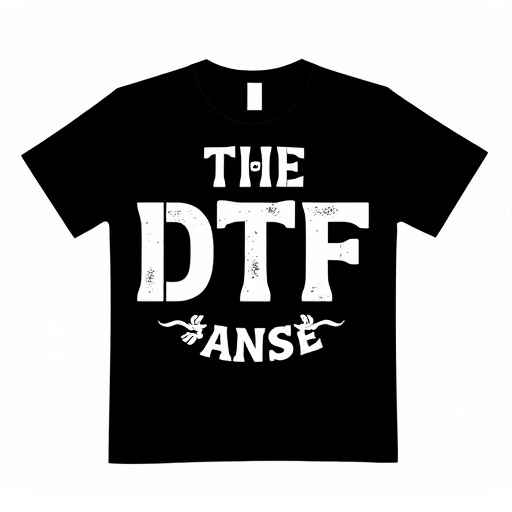

Direct-to-Film (DTF) printing is an innovative technology offering superior durability for film transfers. By directly applying designs to film through heat and pressure, DTF creates prints resistant to fading, scratching, and washing. Ideal for outdoor advertising and artistic murals, DTF prints maintain vibrant colors and intricate details over extended periods, making them perfect for long-lasting applications. Best practices include protecting from moisture and sunlight, regular cleaning, gentle handling, and storage in a cool dry place to preserve the quality of DTF transfers.

Discover the future of print with long-lasting DTF (Direct to Film) transfers. This cutting-edge technology offers unparalleled durability, resisting wear and tear from washing and everyday use. In this comprehensive guide, we explore the science behind DTF printing, its advantages over traditional methods, and essential tips for choosing materials and preserving your prints. From understanding the process to ensuring longevity, learn how DTF transfers are revolutionizing the way we enjoy art and photos.

- Understanding DTF Transfers: A Comprehensive Overview

- The Science Behind DTF Printing: How It Works

- Advantages of DTF Transfers Over Traditional Methods

- Ensuring Durability: Resistance to Washing and Wear

- Choosing the Right Materials for Longevity

- Best Practices for Maintaining and Preserving DTF Prints

Understanding DTF Transfers: A Comprehensive Overview

Understanding DTF Transfers: A Comprehensive Overview

Direct-to-film (DTF) transfers represent a revolutionary advancement in printing technology, offering unparalleled durability and resistance to both washing and wear. Unlike traditional printing methods that rely on ink adherence to a substrate, DTF involves transferring an image directly onto film, creating a robust and long-lasting print. This innovative approach ensures that the design becomes an integral part of the film itself, making it highly resistant to fading, chipping, or peeling over time.

DTF printing leverages advanced materials and techniques to produce high-quality, vibrant prints that maintain their crispness and color accuracy even under extreme conditions. The process begins with a precise application of the design onto the film using specialized equipment, followed by careful curing to ensure long-term stability. This method is particularly favored in industries demanding superior longevity and resistance, from outdoor advertising to artistic murals, ensuring that DTF prints remain visually striking and intact for extended periods.

The Science Behind DTF Printing: How It Works

Direct-to-film (DTF) printing is a cutting-edge technology that revolutionizes the way we preserve and share our memories. This innovative process involves transferring high-quality prints directly onto film, creating a durable and resistant end product. The science behind DTF Printing lies in its ability to bond inks seamlessly with the film’s surface, ensuring long-lasting color vibrancy and clarity.

During the DTF process, specialized printers use a precise application of heat and pressure to fuse inks into the film’s emulsion layer. This direct contact creates a strong chemical bond between the ink and film, making the transfer resistant to fading, scratching, and even harsh washing processes. The result is a vibrant, indelible print that retains its quality for years to come, allowing folks to cherish their cherished moments without worry.

Advantages of DTF Transfers Over Traditional Methods

The advent of Digital Thermal Transfer (DTF) technology has brought about a significant evolution in the world of printing and film transfers. One of its key advantages over traditional methods is durability and resistance to wear and tear. DTF prints are known for their long-lasting quality, ensuring that images and designs remain vibrant and intact even after extensive use or exposure to various environmental conditions. This makes DTF Transfers an ideal choice for applications requiring longevity and resilience.

Additionally, DTF offers a level of versatility not found in conventional techniques. It allows for the reproduction of intricate details and complex artwork with precision, making it suitable for a wide range of products, from clothing and accessories to signs and decorations. The ability to create high-resolution prints directly onto various materials, including fabric, paper, or plastic, expands creative possibilities and caters to diverse client needs in an efficient manner.

Ensuring Durability: Resistance to Washing and Wear

Ensuring Durability: Resistance to Washing and Wear

In the realm of film transfers, DTF (Direct-to-Film) Transfer technology stands out for its remarkable durability. This innovative process creates prints that are not just vibrant but also remarkably resistant to fading and wear over time. Unlike traditional printing methods, DTF Printing employs a unique binding agent that fuses the inks directly to the substrate, resulting in a high-quality, long-lasting finish.

When it comes to resistance to washing and wear, DTF Transfers excel due to their robust bond between the ink and the material. This ensures that even under rigorous use, such as frequent laundry cycles, the prints remain intact and vivid. The advanced formulation of the binding agent prevents color bleeding and smudging, making DTF Prints ideal for items that are frequently handled or exposed to environmental elements.

Choosing the Right Materials for Longevity

When creating long-lasting film transfers, selecting the right materials is paramount to ensure resistance against washing and wear. For instance, DTF (Direct to Film) Transfer technology offers an excellent solution due to its superior durability and vibrant color retention. This method involves printing directly onto a clear substrate, resulting in crisp images that are less susceptible to fading or damage over time. The choice of film quality and ink types plays a significant role; high-quality films with robust coatings and archival inks designed for longevity are ideal.

Additionally, the surface finish and adhesive used should be carefully considered. A matte finish can provide better scratch resistance compared to glossy options, while specialized adhesives ensure secure bonding that can withstand repeated washing without compromising the transfer’s integrity. DTF Printing techniques allow for intricate details and accurate color representation, making them perfect for preserving cherished memories or creating durable art pieces that can withstand the test of time and frequent handling.

Best Practices for Maintaining and Preserving DTF Prints

To ensure your DTF (Direct to Film) transfers remain vibrant and durable, several best practices should be followed. First, avoid exposing prints to excessive moisture or direct sunlight for prolonged periods as these conditions can accelerate fading and damage. Regularly cleaning your DTF prints with a soft, dry cloth is recommended to remove any dust or grime accumulated over time.

When handling DTF prints, it’s crucial to do so gently, avoiding any unnecessary pressure that might cause smudging or physical damage. Storing them in a cool, dry place, away from direct light sources and sharp objects, will further contribute to their longevity. Additionally, consider framing your cherished DTF prints to protect them from environmental elements and everyday wear and tear.