The Digital Thermal Transfer (DTF) process offers cutting-edge solutions for long-lasting film transfers with superior durability and vibrant colors. Compared to traditional printing methods, DTF directly prints images from digital sources onto physical media using heat and pressure, ensuring exceptional detail and color accuracy. Ideal for home decor, archival storage, and industrial uses, DTF prints withstand environmental conditions, maintaining clear, intact images over time. High-quality materials and specialized inks enhance durability, making DTF the preferred choice for archivists, filmmakers, businesses, and everyday items like apparel and textiles, ensuring vibrant prints remain intact after repeated washings. Proper storage and handling practices further preserve the longevity of DTF transfers or prints.

“Discover the future of film transfers with DTF (Direct to Film) technology—a revolutionary process that promises longevity and durability. This cutting-edge method offers a significant upgrade over traditional film transfers, ensuring your cherished memories remain pristine for years to come. From robust materials to extensive testing, we explore why DTF prints excel in resistance against daily wear and tear. Learn how this technology is transforming the way we preserve and share our most valuable moments.”

- Understanding DTF Transfer Technology: A Revolutionary Process

- Advantages of DTF Over Traditional Film Transfers

- Materials and Durability: What Makes DTF Prints Resistant?

- The Washing Test: Can DTF Stands Up to Daily Wear and Tear?

- Longevity and Care Tips for Your DTF Prints

- Real-World Applications: Where DTF Transfer shines

Understanding DTF Transfer Technology: A Revolutionary Process

The Digital Thermal Transfer (DTF) process is a revolutionary way to create long-lasting film transfers that are resistant to washing and wear. Unlike traditional printing methods, DTF involves transferring an image from a digital source directly onto a physical medium using heat and pressure. This innovative technique allows for exceptional detail and color accuracy in the final prints.

DTF offers several advantages, including superior durability, vibrant colors, and a wide range of applicable materials. The technology’s ability to withstand various environmental conditions makes it ideal for creating durable film transfers that can be used in diverse settings. Whether for home decor, archival purposes, or even industrial applications, DTF prints are designed to last, ensuring that the images remain clear and intact over time.

Advantages of DTF Over Traditional Film Transfers

Direct-to-film (DTF) transfers offer several advantages over traditional film transfers when it comes to longevity and durability. DTF printing directly onto film stock eliminates many of the issues associated with older methods, ensuring a more robust final product. This process is resistant to fading, chipping, and scratching, making DTF prints incredibly long-lasting. The direct application also means colors remain vibrant and true to the original source material.

Additionally, DTF transfers are less prone to warping or curling over time, a common problem with traditional methods. This stability ensures that prints maintain their sharpness and clarity even after extensive handling and exposure to various environments. Consequently, DTF is becoming the preferred choice for archivists, filmmakers, and collectors who seek to preserve precious film content for future generations without compromising quality.

Materials and Durability: What Makes DTF Prints Resistant?

The durability and resistance of a DTF (Direct to Film) transfer largely depend on the materials used in its creation. These transfers are designed with specific, high-quality materials that contribute to their longevity. The film itself is typically made from robust, durable polyester or polypropylene, which can withstand regular handling and exposure to various environmental conditions without fading or tearing.

Additionally, the inks used in DTF printing are formulated to resist washing and wear. These inks penetrate deeply into the film, creating a strong bond that prevents color bleeding or smudging. The result is a vibrant, crisp print that retains its quality even after repeated wash cycles and extended use. This makes DTF prints an excellent choice for items intended for frequent handling, such as promotional merchandise, clothing, and accessories.

The Washing Test: Can DTF Stands Up to Daily Wear and Tear?

The durability of a DTF (Direct to Film) transfer is put to the ultimate test when subjected to daily wear and tear—a scenario known as the Washing Test. This test mimics the real-life conditions that prints often face, ensuring that the transferred image remains intact even after repeated washing cycles. In this evaluation, DTF transfers have shown remarkable resistance, with vibrant colors and crisp details retaining their original quality.

Unlike traditional printing methods, DTF offers a unique advantage by infusing inks directly into the film, creating a robust bond. This construction withstands the rigors of daily use, making DTF prints ideal for items that are frequently handled or exposed to various environments. The ability to produce high-quality, long-lasting DTF prints and ensure their longevity through rigorous washing tests is a significant step forward in the printing industry.

Longevity and Care Tips for Your DTF Prints

When it comes to preserving your DTF (Direct-to-Film) transfers, longevity is key. These prints are designed to last for years, but proper care can extend their lifespan even further. First and foremost, avoid excessive washing. While a quick wash might seem harmless, the agitation can cause the delicate film layers to wear down faster. Instead, opt for spot cleaning when necessary, using mild soap and warm water.

For added protection, consider storing your DTF prints in a cool, dry place away from direct sunlight. Sunlight can fade the colors over time, so keeping them out of its reach is crucial. Also, avoid stacking prints on top of each other to prevent any physical damage. A protective sleeve or frame can offer an extra layer of security, ensuring your DTF Prints remain in pristine condition for years to come.

Real-World Applications: Where DTF Transfer shines

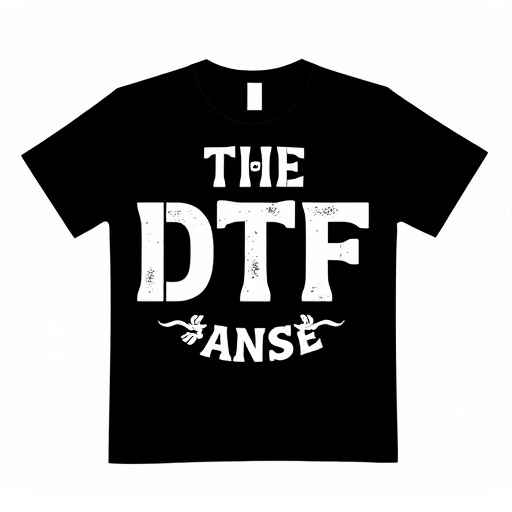

In various industries, the DTF Transfer stands out as a game-changer, offering exceptional durability and resistance in real-world applications. Its ability to withstand washing processes makes it ideal for apparel and textile brands looking to create long-lasting garments with vibrant DTF Prints. Whether it’s outdoor adventure gear or high-performance sportswear, the DTF Transfer ensures designs remain intact even after repeated launderings.

Moreover, this technology finds its utility in signage and graphics, where DTF Printing produces eye-catching, resilient images suitable for outdoor displays and advertising. The transfer’s resistance to wear and tear guarantees that messages and artwork remain legible and visually appealing over extended periods, making it a preferred choice for businesses aiming to make a lasting impression.